NC control allows automatic setting of machining conditions by inputting information on the target workpiece and grinding wheel. In addition, automatic compensation functions (convexity correction and Δh correction) allow processing conditions to be corrected simply by inputting the measured values of test-cut workpieces.

Grinding wheel feed function is provided according to the number of times the grinding wheel is processed to compensate for wheel wear.

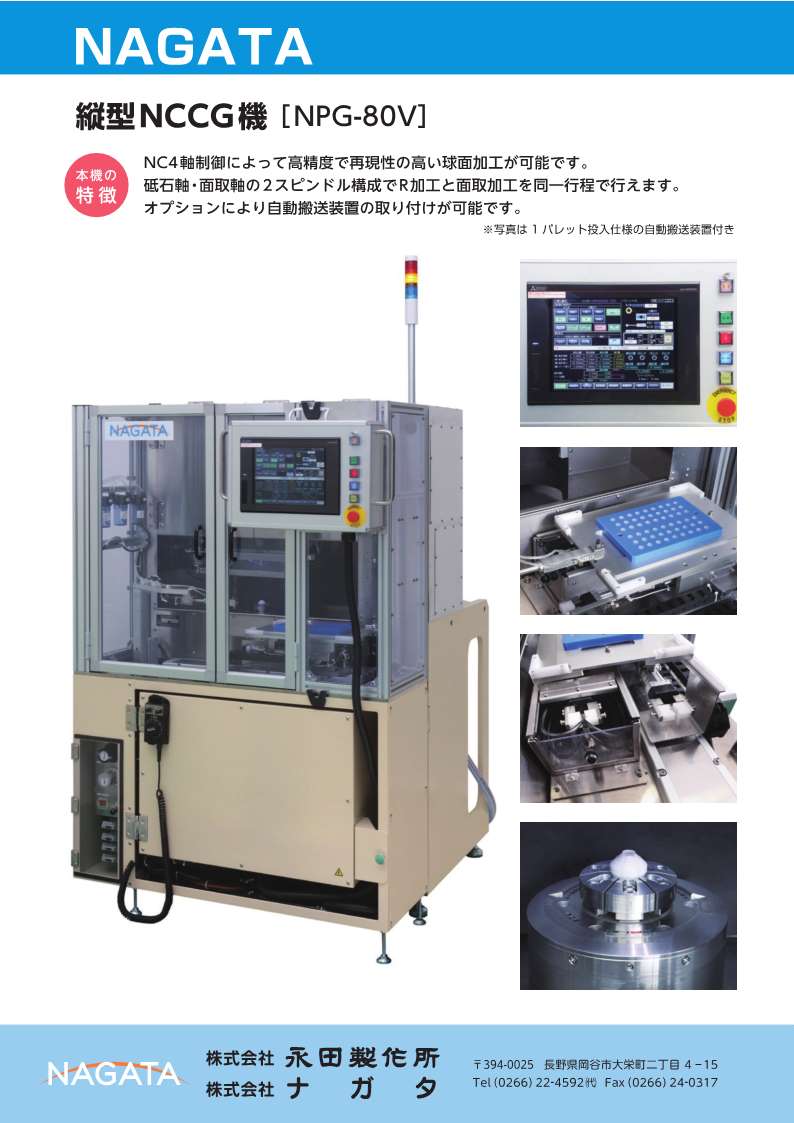

The use of an optional automatic transporter enables automatic feeding of workpieces and continuous processing of workpieces.

A chamfering axis can be attached as an option.

CG Machine

NCCG Machine NPG-80V

NAGATA SEISAKUSHO CO., LTD.

Mass production is also possible with the use of an optional automatic transfer machine.

While general-purpose machines require skill in setup, the NC-controlled automatic compensation function makes spherical surface machining easy.

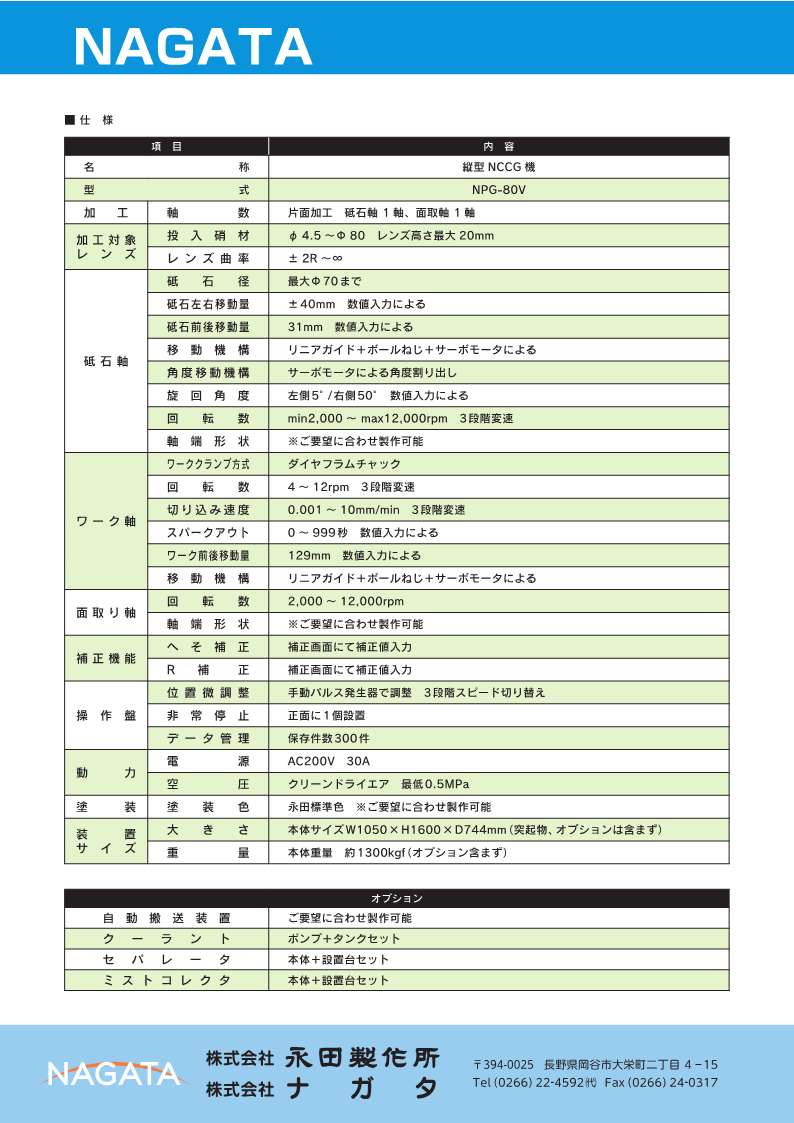

| Lens to be processed | Glass material | φ20~80mm lens height max. 20mm |

| Lens curvature | ±R10mm~∞ | |

| Grindstone shaft | Diameter of Grinding stone | up to max φ70mm |

| Horizontal movment amount | ±40mm by value input | |

| Vertical movement amount | θセンターから-11mm、チャック側へ+20mm input value (Movement in lens direction) |

|

| 移動機構 | Linear Guide+ball screw+servomotor | |

| 角度移動機構 | roller drive+Angle indexing by servomotor | |

| 旋回角度 | 作業差側から見て最大 left side 5°/right side 50° | |

| No. of rotation | 500~8,000rpm(3段階変速設定可) | |

| Motor | 1 unit | |

| No. of spindle | 1 pc | |

| Shaft end shape | 油圧チャック 砥石取り付け部φ30 (Miki pulley ETP-E-25RH) |

|

| Work shaft | Chuck shape | Diaphragm chuck |

| Workpiece clamping method | 樹脂爪 | |

| No. of rotation | 20~1,200rpm(3段階変速設定可) | |

| Motor | 1unit | |

| 切り込み速度 | 0.001~10mm/min input value(3段階変速設定可) | |

| Spark out | 0~999 sec. input value | |

| ワーク前後移動量 | θセンターから上方向-15mm、下方向-144mm input value (ダイヤフラム端面まで(爪含まず)) |

|

| 移動機構 | Linear Guide+ball screw+servomotorによる | |

| Correction function | convexity correction and

Δh correction |

補正画面にて補正値入力 手動にてワークを実測、誤差を入力 |

| Grinding liquid | Supply position | 1系統+中心給水 |

| Tank | 角型タンク | |

| safety device | front door | 加工終了後、一定時間経過後解錠(電磁ロックによる施錠) |

| emergency stop | 1 in control box | |

| Control panel | Touch panel | 10.4 inch. |

| Control panel | Automatic, manual, setting screen, etc. switching display | |

| Fine adjustment | Manual pulse generator adjustment | |

| Data management | 20 pcs can be saved | |

| Running function | 電源投入初回原点復帰時、全ストローク稼働 | |

| Power | Power source | AC200V |

| Air pressure source | Clean dry air 0.5MPa | |

| Dimensions | Approx. W1,050×H1,600×D1,100mm(突起物・搬送機含まず) | |

| Weight | Approx. 1,300kg |