The lens grinding surface is always pressed perpendicularly toward the sphere center to shorten the processing tact time and produce a high-precision radius surface with minimal irregularity, which is particularly effective when grinding concave surfaces.

Processing conditions are NC-controlled to ensure high reproducibility in setup changes.

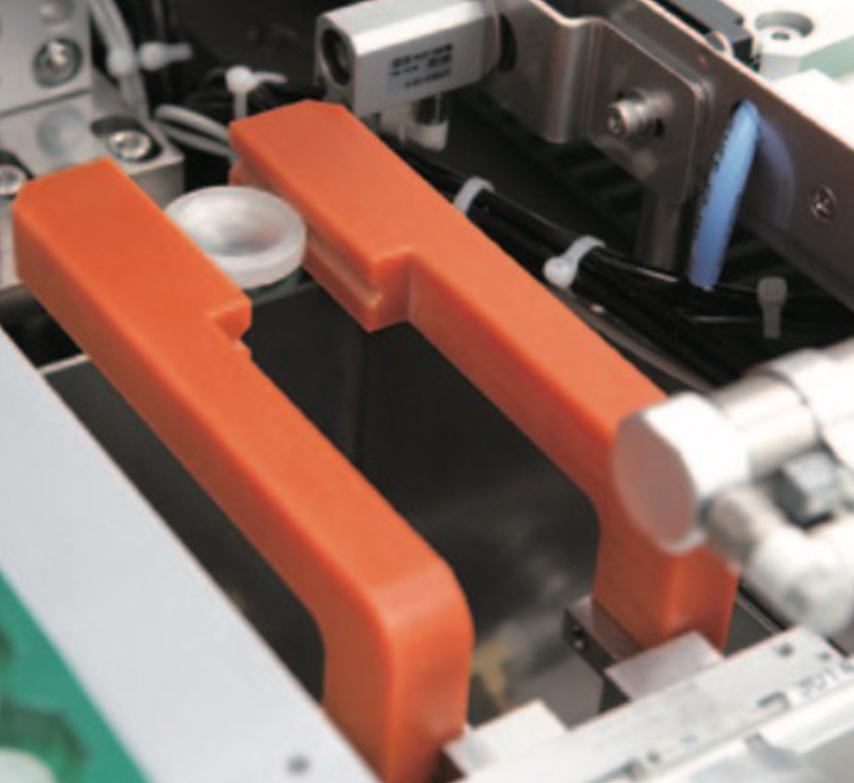

By manually loading the lens tray, the transporter automatically loads the workpiece into the processing section, processes it, and stores it in the tray.

Polishing Machine

Upper Shaft Spherical Core 2-shaft Smoothing Machine with Automatic Conveyor UPA-2S-50-75D

NAGATA SEISAKUSHO CO., LTD.

Automatic processing of deep concave lenses with high precision

「中型上軸球芯加圧研磨機 UP-2P-50」の搬送機付きモデルです。投入トレイごとの連続加工が可能です。

| No. of Shaft | 2(2 shaft 1 drive) | |

| Drive method | Independent rotation of each shaft | |

| Processing R | ±50mm | |

| 最大工具径 | φ100mm | |

| 球芯点 | 皿軸端面から100mm | |

| Water supply function | 軸中心+2系統 | |

| Swing Shaft | Motor | Servo motor 0.75kW with brakes(1/20) |

| 振幅設定 | input value(touch panel) | |

| Rotation speed | 1~36/min. | |

| Speed adjustment | input value(touch panel) | |

| Swing range | Right side facing front 0~75° | |

| Swing angle | 揺動開始位置より振分 one side max. 22.5°(both sides 45°) | |

| Main Shaft | Motor | induction motor 0.2kW 2P 2 units |

| Rotation Speed | 600~2,400rpm | |

| Speed adjustment | Touch Panel Operation | |

| Lock function | シリンダー付ロック機構 | |

| 工具取付ネジ | M16×1.0 female screw | |

| Pressure | Pressurization method | Kanzashi type cylinder pressurization(2-step pressurization) |

| Pressurization switch | Touch Panel Operation | |

| Dimension | Approx. W1,435×H2,070×D1,080mm(not including protruding object) | |

| Weight | Approx. 900kg |

Utility

| air pressure | for pressurization | More than 0.4MPa |

| For adsorption | More than 0.6MPa | |

| Input power source | AC200V 30A |

Automatic supply device

| Tray | 1 tray | Made by OHARA Corporation Standard lens pack can be used |

| beck pattern | 8 patterns can be stored. | |

| driving force | Belt conveyor type | |

| Supply Method | 1パック終了モード・連続供給モード | |

| Washing | Includes simple washing(shower-style) |