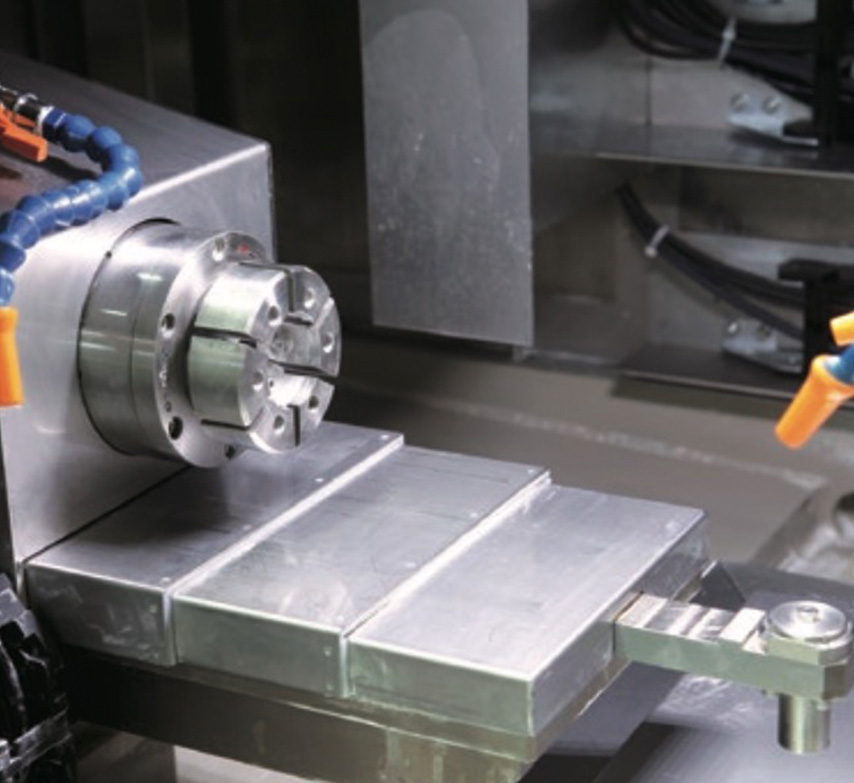

Equipped with three spindles: two spherical machining axes and one chamfering axis. Rough machining→R finishing process→Chamfering processing in 1 chuck.

Equipped with an outside diameter cutting function, the machine is capable of outside diameter cutting using a grinding wheel for R-machining.

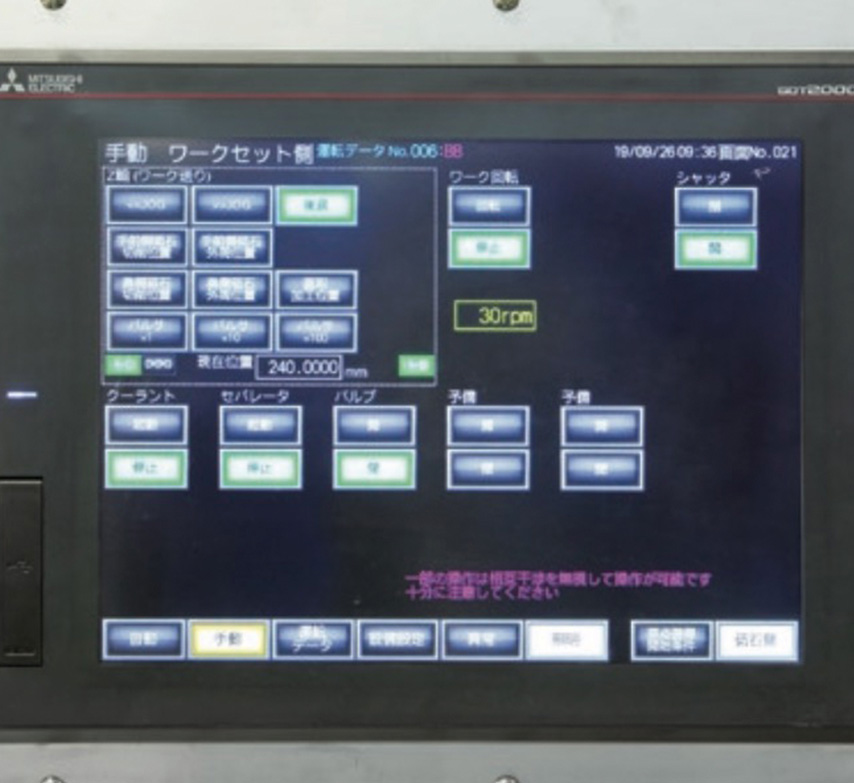

NC control allows automatic setting of machining conditions by inputting information on the target workpiece and grinding wheel. In addition, automatic compensation functions (convexity correction and Δh correction) allow processing conditions to be corrected simply by inputting the measured values of test-cut workpieces.

CG Machine

NCCG Machine NPG-80NC-2

NAGATA SEISAKUSHO CO., LTD.

Three processing axes and one chuck enable processing of three processes.

While general-purpose machines require skill in setup, the NC-controlled automatic compensation function makes spherical surface processing easy.

| Lens to be processed | Lens diameter | φ3~80mm |

| Lens curvature | ±R1.5mm~∞ | |

| Grindstone shaft | Diameter of Grinding stone | maxφ70mm |

| Horizontal movment amount | Centered on workpiece shaft ±120mm inpu value Movement from the worker to the back direction |

|

| Vertical movement amount | θ Chuck side from swivel center +20~=10mm input value Movement in lens direction |

|

| Grinding stone shaft moving mechanism | Linear guide + ball screw + servo motor | |

| Angle | operator-side 0~ inner size 55° | |

| Swivel movement unit | roller drive+Angle indexing by servomotor | |

| No. of rotaion | 1,500~12,000rpm(3-step variable setting possible) | |

| Motor | SP motor 0.4kW 2 units | |

| No. of spindle | 2 | |

| Shaft end shape | Depends on customer specifications | |

| Work shaft | Chuck shape | Diaphragm chuck |

| Workpiece clamping method | resin+金属ヤトイに連続をセットしクランプ | |

| No. of rotation | 10~400rpm(3-step variable setting possible) | |

| Motor | SP motor 120W 1 unit | |

| 切り込み速度 | 0.001~10mm/min input value(3-step variable setting possible) | |

| Spark out | 0~999 sec. input value | |

| Workpiece forward/backward movement | 0~-250mm from swivel center input value | |

| Work shaft moving mechanism | Linear guide + ball screw + servo motor | |

| chamfering shaft | No. of rotation | 1,500~12,000rpm input value |

| Motor | SP motor 120W 1 unit | |

| Shaft end shape | Depends on customer specifications | |

| Correction function | convexity correction and Δh correction | Enter correction values on the correction screen Manually measure the workpiece and input the error |

| Grinding liquid | Supply position | 1 on workpiece side, 3 on grinding wheel side(supplied by one pump(0.2kW)) |

| Tank | SUS square tank Equipped with centrifugal separator | |

| safety device | front door | Closed by button to start processing and opened after processing is completed Locking by air cylinder |

| emergency stop | 1 piece on the upper front | |

| Control panel | Touch panel | 12 inch. |

| Screen | Auto-mode, Manual mode, Set-up mode, etc | |

| position fine-tuning | Manual pulse generator adjustment(3-step speed switching) | |

| Data management | Number of registered sequencer: 100 | |

| Power | Power source | AC200V 30A |

| Air pressure source | Clean dry air 0.5MPa | |

| Dimension | Approx. W1,500×H1,845×D1,120mm | |

| Main Body Weight | Approx. 1,600kg |